What Are You Looking For?

What Are You Looking For?

The automotive air conditioning condenser is a crucial heat exchange component in the air conditioning system, often referred to as the "cooling heart" of the system. Based on structural features, automotive air conditioning condensers are mainly classified into serpentine condensers and parallel flow condensers.

Tube-and-Fin(Serpentine) Condenser

Condenser For Toyota Hilux 1994-1995

Condenser For Toyota Hilux 1994-1995

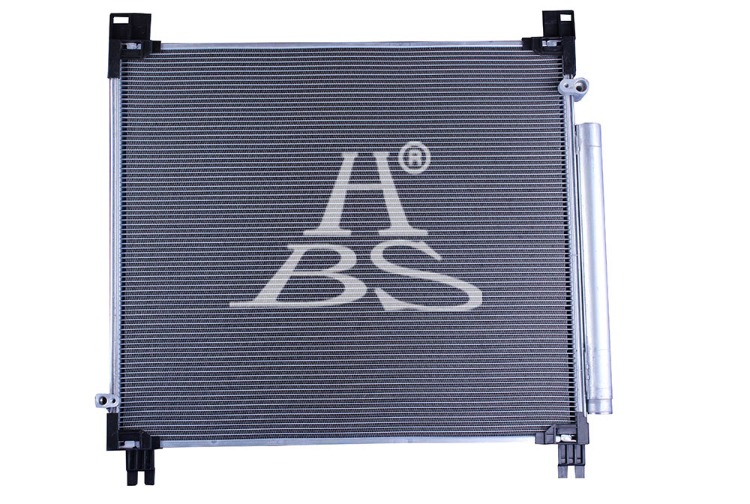

Parallel Flow Condenser

Structural Features: Flat multi-channel tubes + louvered fins + manifold

Technical Advantages:

Applications: Mainstream configuration in modern vehicles

Condenser for Hilux Pickup 2016

Enhanced Parallel Flow Condenser Design:

Reinforced Design: Increased fin density by 40-50%, further refinement of microchannels, material and welding process enhancements

Special Performance: Adaptability to extremely high temperatures (>45°C), further increase in heat dissipation capacity by 15-20%

Applications: new energy vehicles and other high heat load scenarios

Selection and Maintenance Key Points

1.Principles of Correct Selection:

2.Key Points for Routine Maintenance:

In Conclusion

The automotive air conditioning condenser serves as the core heat dissipation component of the air conditioning system, evolving technologically from traditional tube-and-fin types to modern parallel flow designs, always focused on improving efficiency, reducing weight, and minimizing size. Understanding the characteristics and functions of different condensers not only aids in vehicle design and maintenance but also helps users better operate and maintain automotive air conditioning systems.